Have you ever wondered how the oil you’re vaping made it to your hands? We’re breaking down our entire process, step-by-step. Ready, set, Bloom!

Step one – Flower:

Collect high-quality cannabis plant material (about 800-1000 lbs.) from our licensed suppliers.

7 days

Step two- Pre Batch Analysis – 1st R&D testing

Once we receive the leafy plant material of cannabis, our team performs the 1st R&D testing and pre-batch analysis on the batch. We extract a small sample from the plant to make sure the concentrate is void of any pesticides. This step is optional, but we prefer to small a run it before extracting the whole quantity. For this step we use a dedicated equipment to avoid contaminating our main extraction machine in case if the flower is contaminated.

Step three – Extraction:

After the batch passes the required testing we begin to extract the THC from the plant material using Atlas (Capna Systems equipment) at ethanol at cryogenic temperatures. This method and process does not require any winterization, saving time and energy.

- “Ethanol Extracted”: since we use organic ethanol (200 proof alcohol) at a very low temperature, it is much more delicate on the plant (no heat or pressure), and therefore does not pull any of the unwanted lipids/fats/waxes from the plant. We also recycle over 90% of the ethanol we use so it’s not only more efficient, but it’s also a greener process (uses 1/10 the amount of power that is required for CO2 extraction)!

a. We perform what you we call a “sub-zero” wash- pour cold ethanol over the flower to capture the trichomes, THC and cannabinoids. Similar to making tea using loose leaf tea, but we do this 5 times and are able to capture 98-99% of all THC and cannabinoids. Much more efficient than CO2 where you only yield between 70-80%.

b. Ethanol extraction is not a new technology but we were the first to apply it to cannabis. It has been used in other industries such as cosmetics and pharmaceuticals.

c. Safer than traditional extraction method because we are using a non-volatile solvent.

Step four – Reduction:

Once the ethanolic extract of cannabinoids is produced, it goes through reduction using the FFE system by Capna. This is done to separate the crude cannabinoids from the ethanol, which allows us to save resources and recycle the ethanol for the next extraction.

Step five- 2nd R&D test:

After extraction and reduction, the crude oil created is sent through another round of compliance testing. All these measure allow us to prevent any future issues with the final product.

Step six- Decarboxylate:

The crude oil then undergoes a process called decarboxylation, which activates the THC from its THCa counterpart.

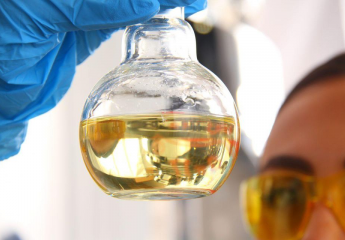

Step seven- Distillation:

The oil is then passed to our distillation team for triple distillation to remove any remaining impurities.

Step eight- 3rd R&D test:

Once we receive the distillate, we test the oil again.

Step nine-Formulation:

Once the quality terpenes are approved per compliance testing, we move forward with our formulation process. Our lab formulates a unique blend of terpenes and triple-distilled cannabinoid distillate to complete homogenous Bloom strains.

Bloom reintroduces up to 50-70 terpenes native to the cannabis strain. The goal is to recreate the original cannabis strain, but in concentrated format replicating both flavor AND effect.

Step ten- Fill, tube, & package:

After the oil has been fully formulated it is inserted it into ccell cartridges using a filling machine, and then placed in child-resistant tubes and put into their final packaging.

Step eleven – Compliance testing:

Once the product has been packaged and labeled, a third-party testing lab (cannasafe in CA) pulls random samples from our batch to perform quality assurance testing.

Step twelve- Labeling:

After we receive the test results, we attach the final label that includes potency and other required test results.

The whole process takes up to 44 business days and the product is tested at every stage through the process to ensure it meets our quality and purity standards.